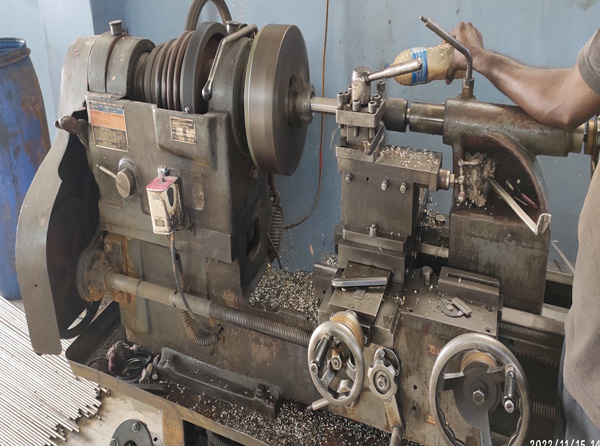

Mechanical testing of metals involves evaluating the mechanical properties of a material to understand its behavior under various forces and conditions.

These tests help assess the material's suitability for specific applications, quality control, and research purposes.

- Tensile Test (Yield & Offset): Measures the Tensile Strength, Yield strength, Proof Strength, % Elongation and % Reduction of area.

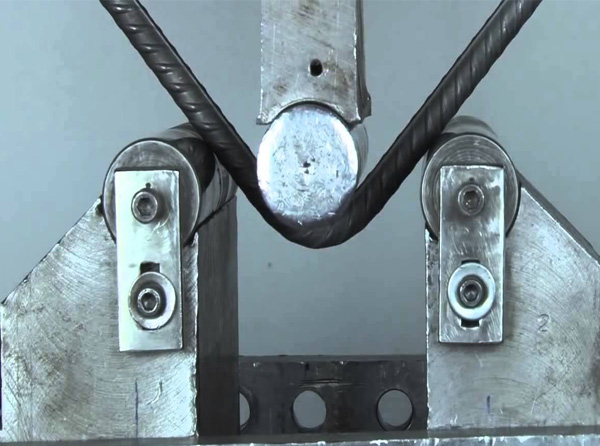

- Bend Test (Base, Root Bend, Face Bend, Side Bend) & Rebend Test for TMT bar: Evaluates the ductility and bending properties of materials.

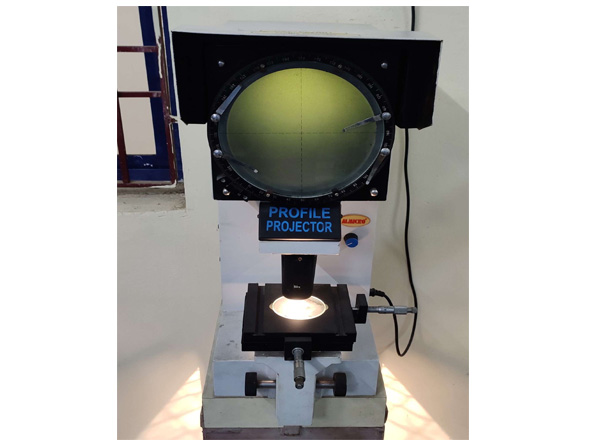

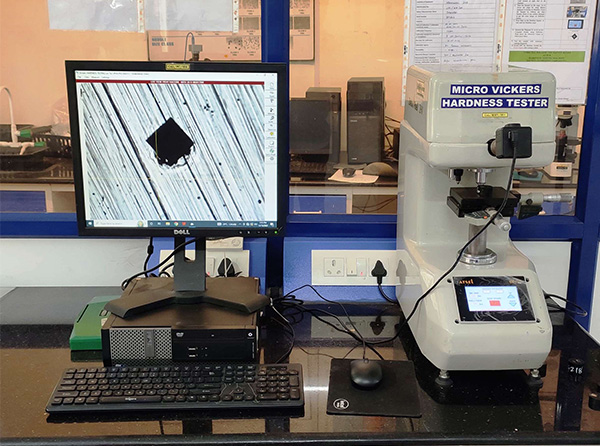

- Hardness Testing (Vickers-HV, Rockwell-HRB, Rockwell-HRC, Brinell-HBW, and Survey for Welds): Determines the hardness of materials using various scales and methods.

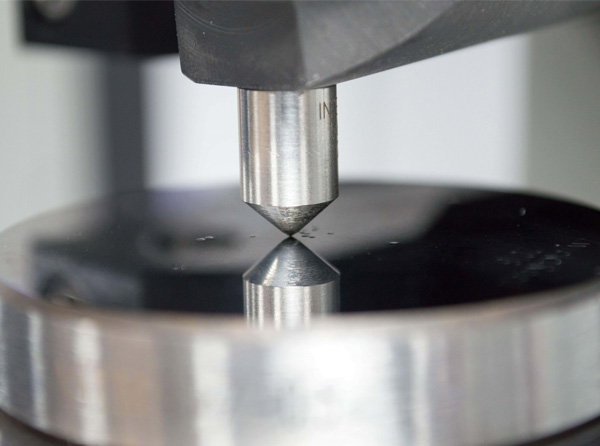

- Micro Hardness Testing (HV0.1,0.2,0.3,0.5,1.0kgf loads): Determines the hardness of materials on Thin sheet, Heat treated steel at particular point location and traverse reading to understand its variation.

- Impact Test (Charpy and Izod @ Room to Sub zero °C temperatures): Assesses the material's toughness and ability to absorb energy at different temperatures.

- Load & Compression Testing: Evaluates the compressive strength and behavior under load.

- Building Material Testing: Tests the strength, durability, and quality of construction materials.

- Weld Testing (WPS, PQR, EQT): Ensures the quality and compliance of welding procedures and welds.

- Fracture & Nick Break Testing: Analyzes the fracture properties and integrity of materials.

- Proof Load Testing (Fasteners): Verifies the strength and durability of fasteners under load.

- Flattening, Flaring, Drift Expansion & Crush Testing: Tests the mechanical properties and deformation behavior of materials.

- Pull / Push Out Testing: Measures the adhesion and bonding strength of materials.

- Mass per Metre for TMT bars.