Non-destructive testing (NDT) of metals is a set of techniques used to evaluate the properties, integrity, and quality of materials without causing any damage to the tested components. These methods are crucial for ensuring the reliability of materials and structures in various industries.

- Ultrasonic Testing: Uses high-frequency sound waves to detect internal flaws in materials.

- Magnetic Particle Testing: Identifies surface and near-surface defects in ferromagnetic materials.

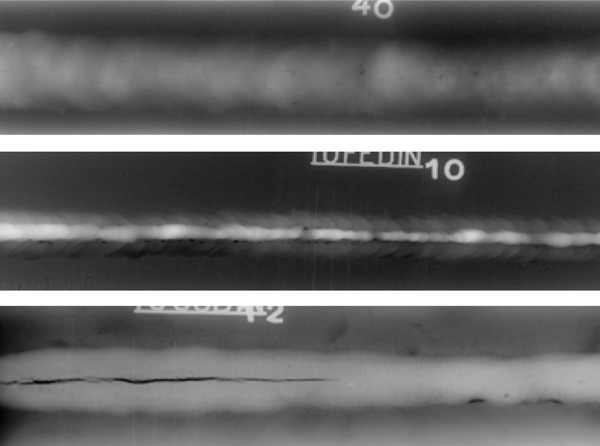

- Radiography Testing: Uses X-rays or gamma rays to inspect the internal structure of materials.

- Dye Penetrant Testing: Detects surface-breaking defects in non-porous materials.

- Visual Inspection: The first line of defense in defect detection, involves careful visual examination.

- Portable Hardness Testing: Allows on-site hardness testing of metals and alloys.

- Coating Thickness Testing: Measures the thickness of coatings applied to metal surfaces.

- Positive Material Identification (PMI): Confirms the composition of metallic alloys.

- Crack Investigation: Detects and analyzes cracks in materials to determine their cause and extent.