Metallography is a microscopic study of the structure of metals and alloys. Metallographic testing is the process of preparing and examining metal samples to understand their microstructure, which includes aspects such as grain size, phases present, and the distribution of different constituents.

- Microstructure Analysis: Examines the microstructure of metals to identify phases, grain size, and other structural features.

- Grain Size Examination: Determines the grain size of metals, which affects their mechanical properties.

- Inclusion Rating Identifies and rates non-metallic inclusions within the metal.

- Coating Thickness Measurement: Measures the thickness of coatings applied to metals to ensure they meet specifications.

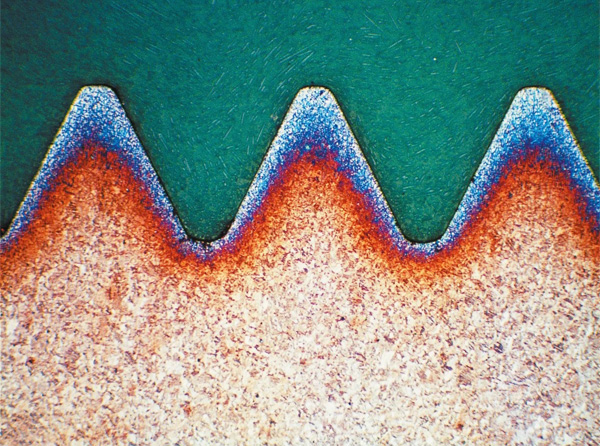

- Nitriding layer Measurement: Measures the Nitriding layer depth of metals surface hardening process.

- Case & Decarb Depth Measurement: Evaluates the depth of case hardening and decarburization in metals.

- Volume Fraction of Phases: Analyzes the volume fraction of different phases in a metal sample.

- Macro & Grain Flow Analysis: Studies the macroscopic structure and grain flow patterns in metals.

- Ferrite Count: Measures the amount of ferrite in steel and other iron-based alloys.

- Porosity Percentage: Assesses the porosity level in metals which can affect their mechanical properties.

- Nodules & Flake Analysis: Examines the nodularity and flake structure in cast iron and other alloys.

- Dimensions Measurement: Precise measurement of dimensions for quality control and specification compliance.

- Failure Analysis: Investigates the causes of material failure to prevent future occurrences.

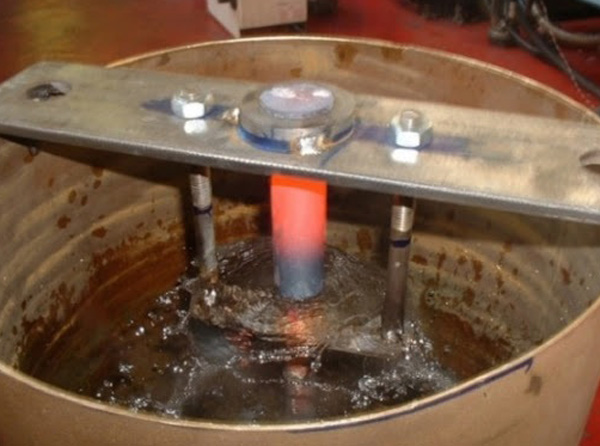

- Jominy End Quench test: Assess the hardenability of a steel alloy by measuring the hardness along the length of a cylindrical sample after quenching.

- Classification of Etch Structures of Duplex Stainless Steels